GIS based work order management is becoming an essential part of asset management for many utility companies. GIS not only is able to track the location of assets but provide vital support to the operations and maintenance division. Hand held or mobile PDAs or tablets are being extensively used to disseminate work order that not only include the location address but also the work order information. Most of these are web based and work order management is becoming the norm rather than the rule. Web based work order allow maintenance crews to have live access to web servers with the GIS data synchronised together with the hand-held devices. GIS based work order are geared to provide the following facilities:

- Linking work orders to mapped features.

- Provide search parameters based on mapped features.

- Build maintenance schedule based on map locations.

- Provide customised locational query-based results.

- Track work order type and costs involved.

- Provide emergency replacements and justify rate increases

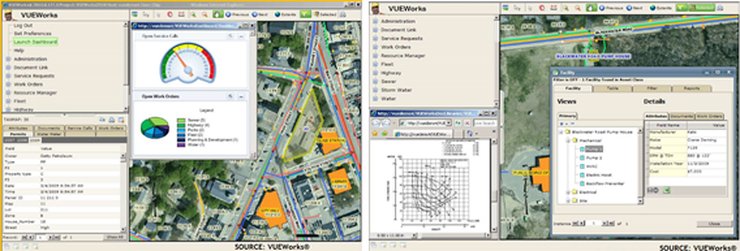

There are multiple products in the geospatial market that have integrated GIS with utility assets operation and maintenance. Software solutions like CityWorks™ and VueWorks™ not only provide customisable service requests, work orders, and inspection tasks but also have intuitive tools, tabs and links that further extend GIS functionalities.

Work order processing has evolved from traditional pen and paper which was time consuming, prone to error and inefficient and has been replaced by manual web-based entry forms but still prone to entry errors though partly efficient. It must be reiterated that automation of workflow processes will not only make manual entry redundant, but will be more efficient and error free. It must be emphasized that asset operation and maintenance is intricately linked to business bottom-lines and ROIs and hence automation of some of the work order processes will provide that extra edge.

This article focuses on how work order management can be automated for field crews so that it helps in streamlining some of the process and provide significant benefits and cost savings.

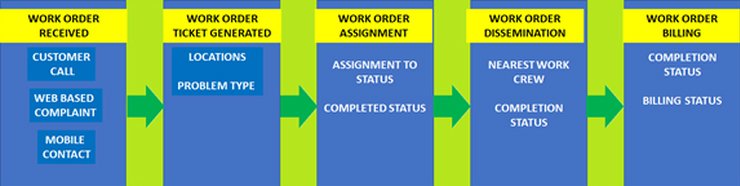

To understand how automation process will help streamline the work order process, it is important to important to first focus on the present workflow and problems faced. A simplified work order processing is provided below:

The problems of work order processing are mainly linked to the following:

- Access to information is restricted.

- Data entry and re-entry of location and work order information time consuming.

- Repeatable processes lead to errors or mistakes.

- Loss of information due to various technical, natural and human error.

Due diligence is required for understanding the various problems and subsequent automation workflow can be devised. For example, consider an area that has electricity blackout due to a malfunctioning substation. The customer provides the information through the call center and BOT picks up the complaint, generates a ticket and provides the nearest maintenance crew the information relating to the malfunctioning substation. An optimal route to reach the substation is also provided to the maintenance crew. Once the malfunction is rectified and electricity restored, the maintenance crew closes the ticket and status of the work completed is updated in the work order management system.

Automation software solutions provide the means through which existing applications can be integrated. The benefit of such solutions emulates human action, high volume repeated tasks, perform simultaneous tasks, automate report generation, information validation and audit trail, etc. Apart from the above benefits these are solutions that require 3 -4 weeks at most to integrate with existing systems, adapt easily and configurable to change in business rules, works 24 x 7, digital workforce increased or decreased according the demand.

Automating work order processing and interfacing with GIS Utility mapping solution allows utility businesses to not only save costs but helps in streamlining the work order from initiation to final close out.